Compliance and Safety Audits

In an ever-evolving regulatory landscape, Virtual Edge 4D (VE4D) is at the forefront of compliance and safety audits across a multitude of industries in Australia, including mining, agriculture and uncrewed aircraft operations (ReOC holders). Our comprehensive analysis and tailored solutions are designed to ensure that your operations not only meet but exceed industry standards, fostering a culture of excellence and safety.

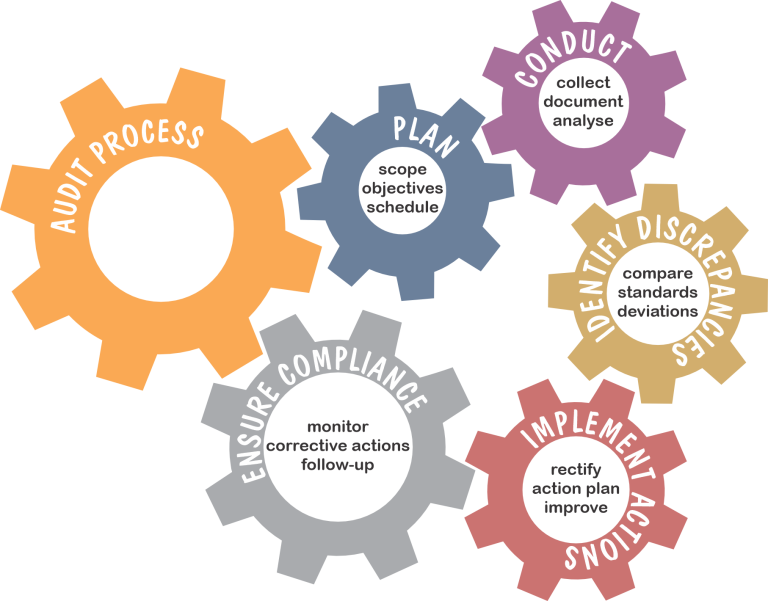

This approach ensures a rigorous and systematic audit process that enhances operational efficiency and regulatory compliance.

VE4D’s commitment to quality is underscored by our adherence to ISO 9001 standards, the globally recognised benchmark for quality management systems. By integrating ISO 9001 principles into our auditing processes, we provide a structured and systematic approach to achieving operational excellence. Our services ensure that businesses meet their legal obligations and operate in accordance with relevant legislation and standards, minimising risks and enhancing overall performance.

Our meticulous auditing process includes:

- Detailed compliance checks tailored to specific industry requirements

- Thorough safety assessments to identify and mitigate potential hazards

- Comprehensive reporting and actionable insights for continuous improvement

- Assistance with certification processes to ensure regulatory compliance

- Ongoing support and follow-up audits to maintain high standards

Join the ranks of industry leaders who trust VE4D to safeguard their operations and drive continuous improvement. With our expertise and dedication, you can rest assured that your business is in capable hands.

Mining

Mining operations are subject to several key audits to ensure safety, compliance, and environmental responsibility, including:

Safety and Health Management Systems (SHMS) Audit: This audit evaluates the effectiveness of the mine's safety and health management systems, ensuring they meet regulatory requirements and industry standards.

Environmental Management Systems (EMS) Audit: This audit assesses the mine's environmental management practices, ensuring compliance with environmental regulations and sustainable practices.

Operational Safety Audits: These audits focus on specific operational activities, such as drilling, blasting, and mobile equipment management, to identify and mitigate potential hazards.

Compliance Audits: These audits ensure that the mining operation adheres to relevant legislation, regulations, and industry standards, including ISO 9001 for quality management systems.

Incident and Accident Investigation Audits: These audits review incidents and accidents to identify root causes and implement corrective actions to prevent future occurrences.

Equipment and Machinery Audits: These audits evaluate the condition and maintenance of mining equipment and machinery to ensure they are safe and operational.

Community and Stakeholder Engagement Audits: These audits assess the mine's engagement with local communities and stakeholders, ensuring transparent and effective communication.

By conducting these audits, mining operations can maintain high standards of safety, environmental responsibility, and regulatory compliance.

Agriculture

Crop spraying operations are subject to several key audits to ensure safety, environmental protection, and regulatory compliance, including:

Work Health and Safety (WHS) Audits: These audits ensure that crop spraying operations comply with WHS regulations, focusing on risk management, worker training, and the use of personal protective equipment (PPE).

Environmental Management System (EMS) Audits: These audits assess the environmental impact of spraying practices, ensuring compliance with environmental regulations and promoting sustainable practices.

Pesticide Use and Handling Audits: These audits evaluate the proper use and handling of pesticides, ensuring that operators follow label instructions, maintain proper storage, and dispose of waste safely.

Spray Drift Management Audits: These audits focus on minimizing spray drift to prevent off-target movement of pesticides, which can harm non-target areas and organisms.

Equipment Calibration and Maintenance Audits: These audits ensure that spraying equipment is properly calibrated and maintained to achieve effective and efficient application.

Record-Keeping and Documentation Audits: These audits review the records of spraying activities, including application rates, weather conditions, and equipment checks, to ensure compliance with regulations and best practices.

By conducting these audits, crop spraying operations can maintain high standards of safety, environmental responsibility, and regulatory compliance, ensuring effective pest control and sustainable farming practices.

Uncrewed Operations

Uncrewed aircraft operations conducted by ReOC holders and are subject to several key audits to ensure safety, compliance, and risk management, including:

Civil Aviation Safety Regulations (CASR) Compliance: CASR Part 101 sets out the rules for the use of unmanned aircraft, including RPAS. Operators must comply with regulations regarding locations, altitudes, flight distances, and times of use to ensure safe operations.

RPA operators must register their drones with the Civil Aviation Safety Authority (CASA) and adhere to specific rules and regulations to ensure safe and incident-free operations. This includes restrictions in relation to flying over people, maintaining visual line of sight, and operating in the vicinity of aerodromes.

Manual of Standards (MOS) Part 101 Compliance: The MOS provides detailed requirements for drone operations, including operational procedures, training, and maintenance. Compliance with MOS ensures that drone operations meet the necessary safety standards.

The MOS outlines the acceptable means of compliance and guidance material for RPAS operation. It includes requirements for risk assessments, operational procedures, and training to ensure that RPAS operations are conducted safely and in accordance with regulatory standards and in accordance with the documented practices and procedures.

Basic Aviation Risk Standard (BARS): BARS is an internationally recognised program that provides a standard for managing aviation risks. It involves a thorough evaluation of an operator's safety management systems, emergency response procedures, crew training, and maintenance practices. Achieving BARS accreditation demonstrates a commitment to safety and operational excellence.